| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

| Process: | Epoxy Bonding | Temper: | T3-T8 |

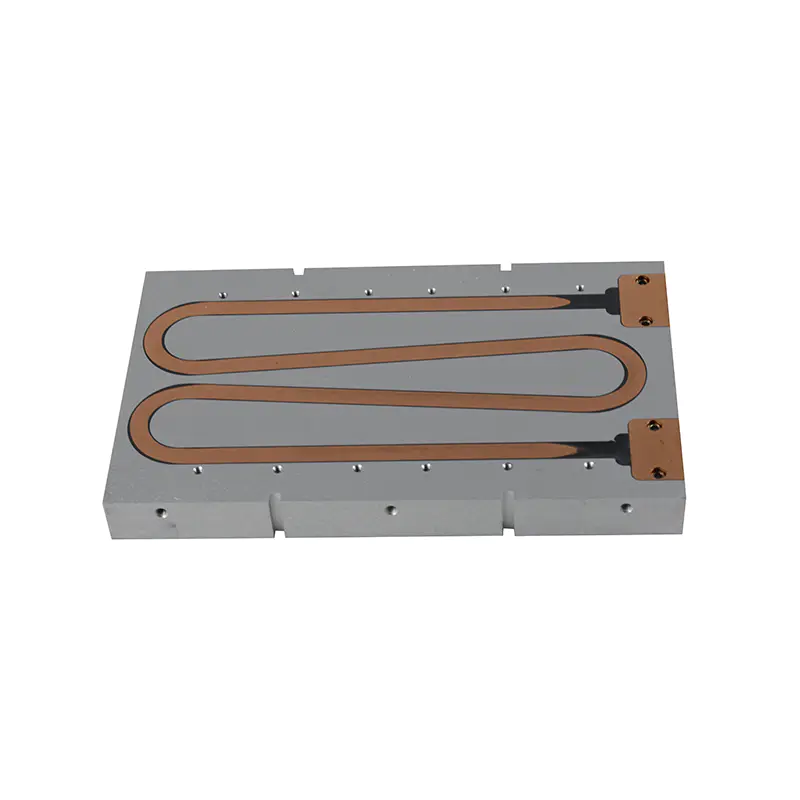

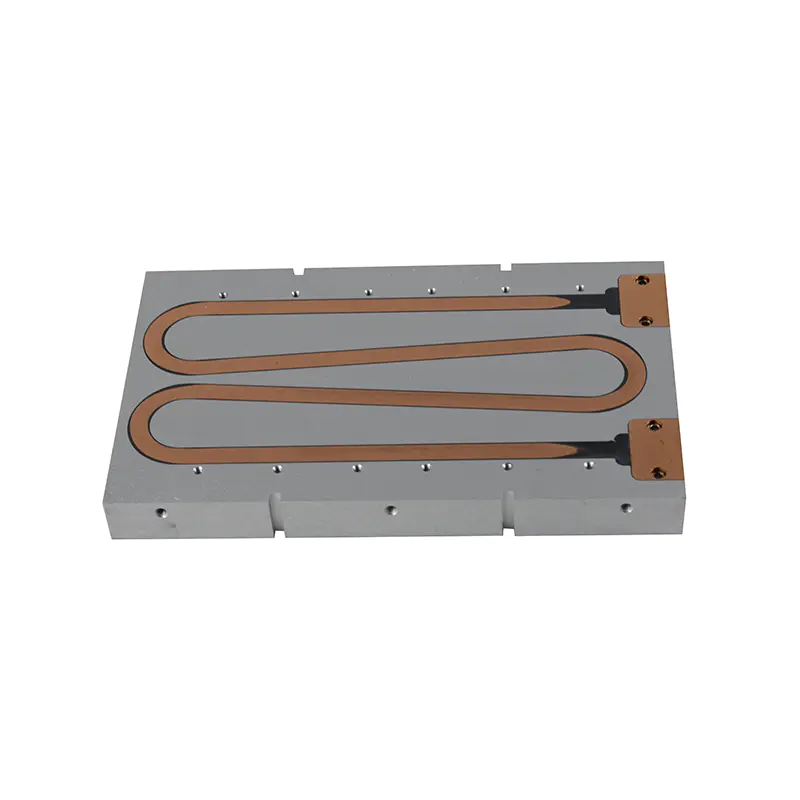

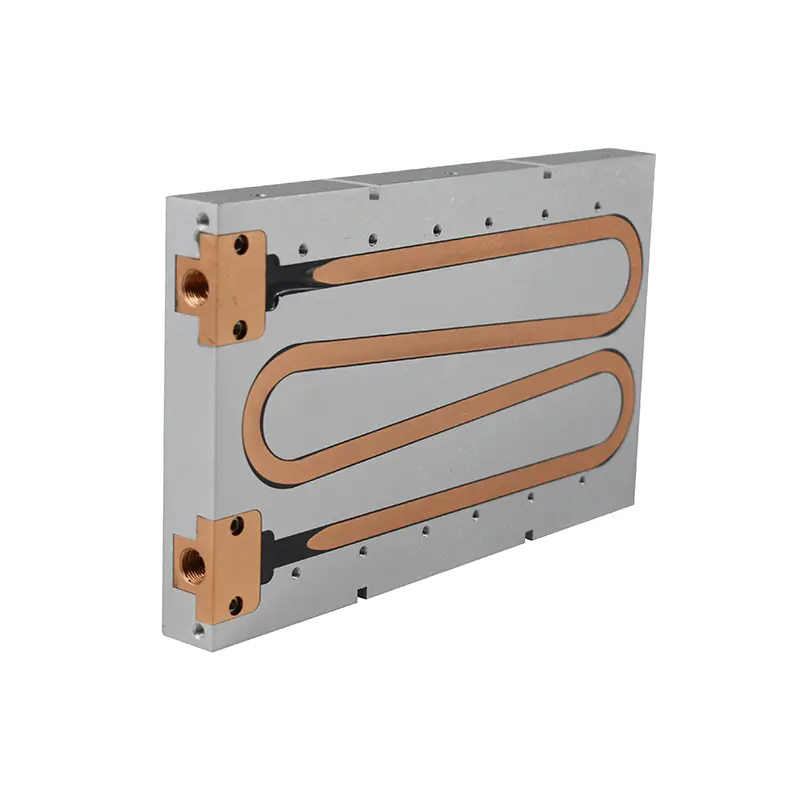

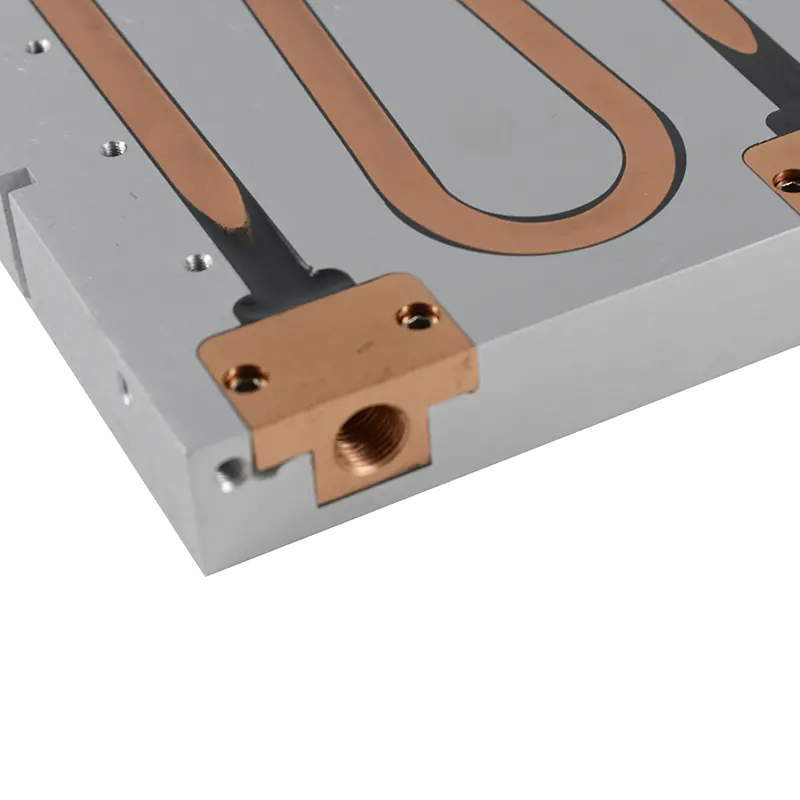

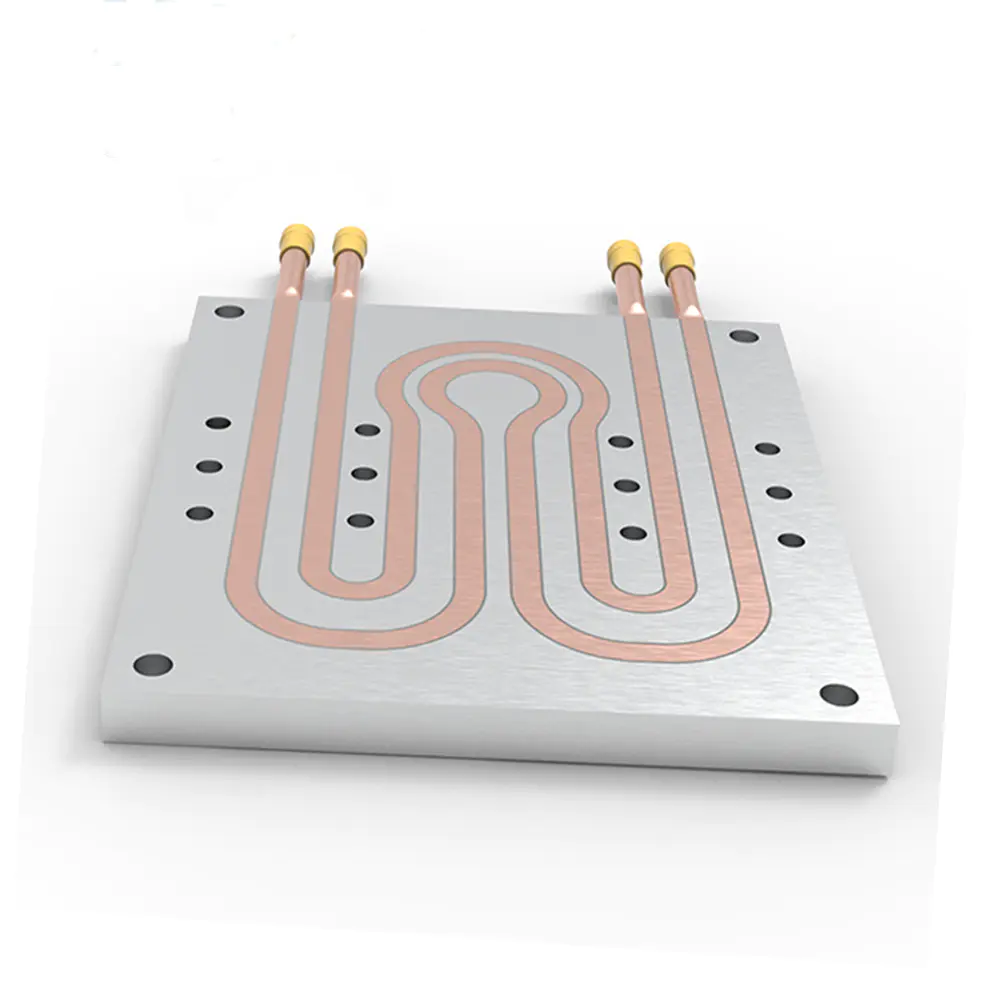

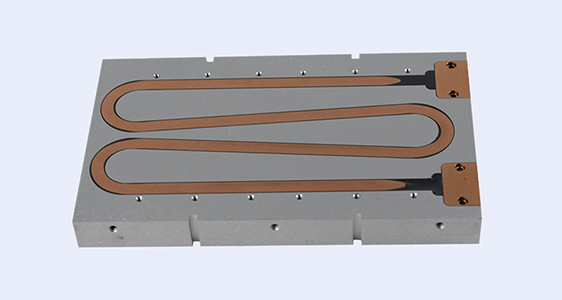

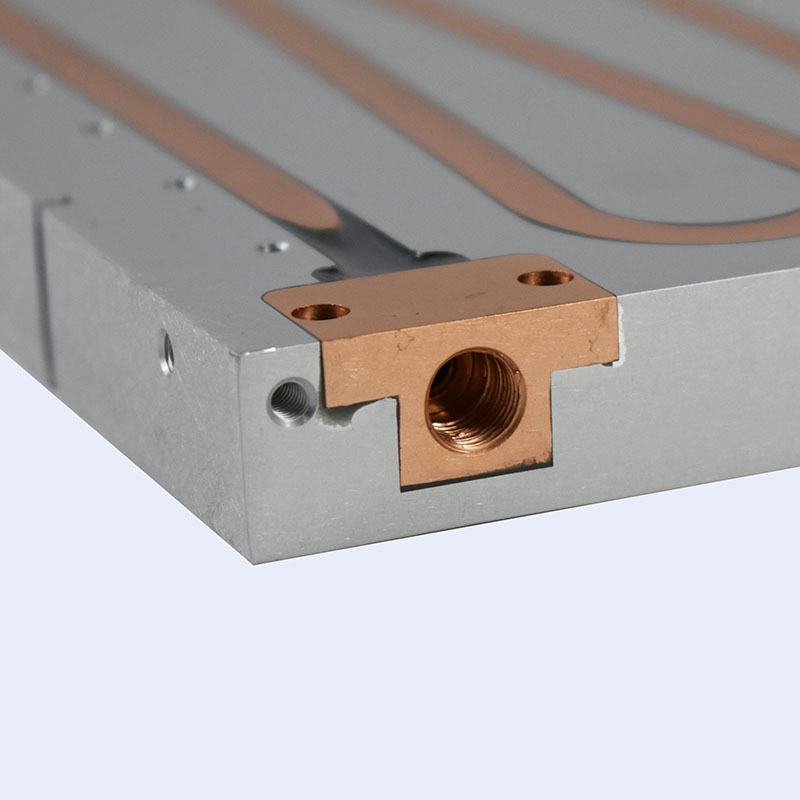

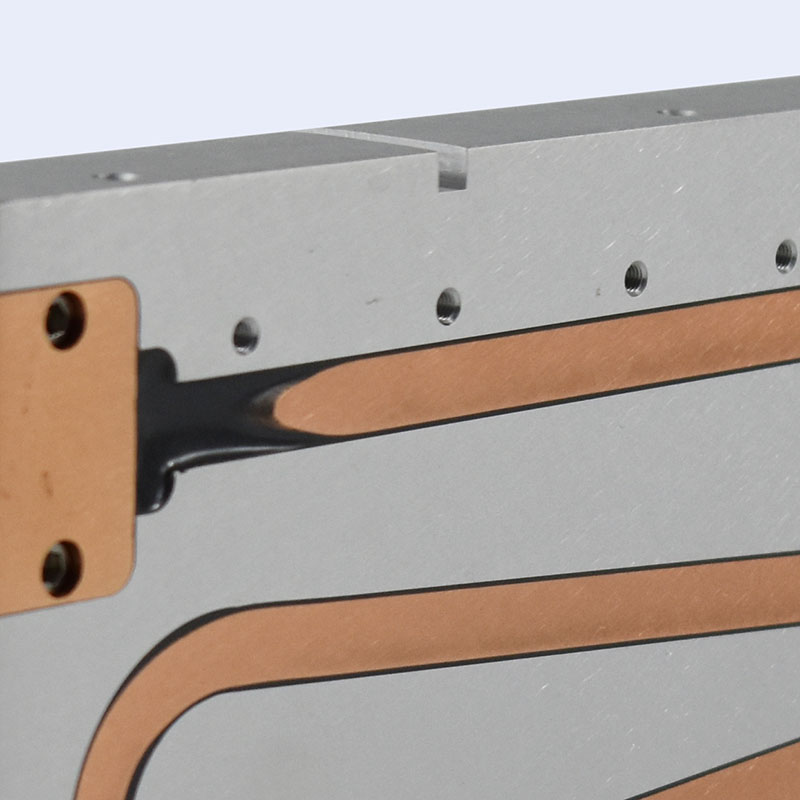

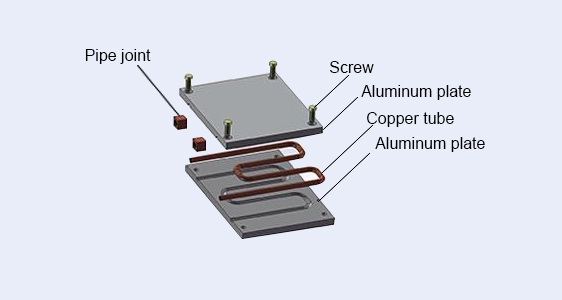

| Material: | Copper heat pipe+ Aluminium cold plate, | Shape: | Square |

| Packing: | Standing Export Packing

| Brand Name:

| LORI

|

| Application: | RGB laser light source | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | LR0019 | Tolerance:

| 0.01 mm |

| Finish: | Clean+Anodized | Quality control: | 100% thermal test |

| Extra process: | CNC Machining | Size: | Custom size |

| Applied Field: | New energy automobile , UPS and energy storage system , large server, large pv inverter , SVG/SVC , etc |

The aluminium cold plate heat sink liquid cooling for igbt made using buried welding technology can effectively avoid the leakage risk of the infusion pipeline, and the liquid flow is large, the conduction heat resistance is low, and the double-sided device can be installed.

we are providing you with the thermal design, structural design, pipework assembly design of liquid cooling and aluminium cold plate heat sink and one-stop supplementary services.

The features of aluminium cold plate heat sink liquid cooling for igbt are:

1. The highest cost performance;

2. Low cost: basically no mold expense is generated, and there is no limit on production volume;

3. High reliability: the channel is made of seamless copper pipe bent and inserted into the substrate groove. As long as the size control is reasonable, there is basically no risk of liquid leakage, and it can withstand pressure above 6kg/cm2;

4. Heating elements can be installed on both sides to minimize the structure;

5. Aluminium cold plate can be inserted into the copper pipe at the same time compressed, and do milling surface processing, so that the surface of the copper pipe exposed plane and substrate in the same plane, to achieve direct contact with heating elements and copper pipe, the heat quickly direct away.

The heat pipe on this aluminium cooling plate is used exposed pipe technique. The techniques for the aluminium cold plate heat sink include the exposed pipe technique, half buried pipe techniques, sandwiched pipe technique. Let us introduce what is full buride pipe techique for aluminium cold plate , please see the following introduction.

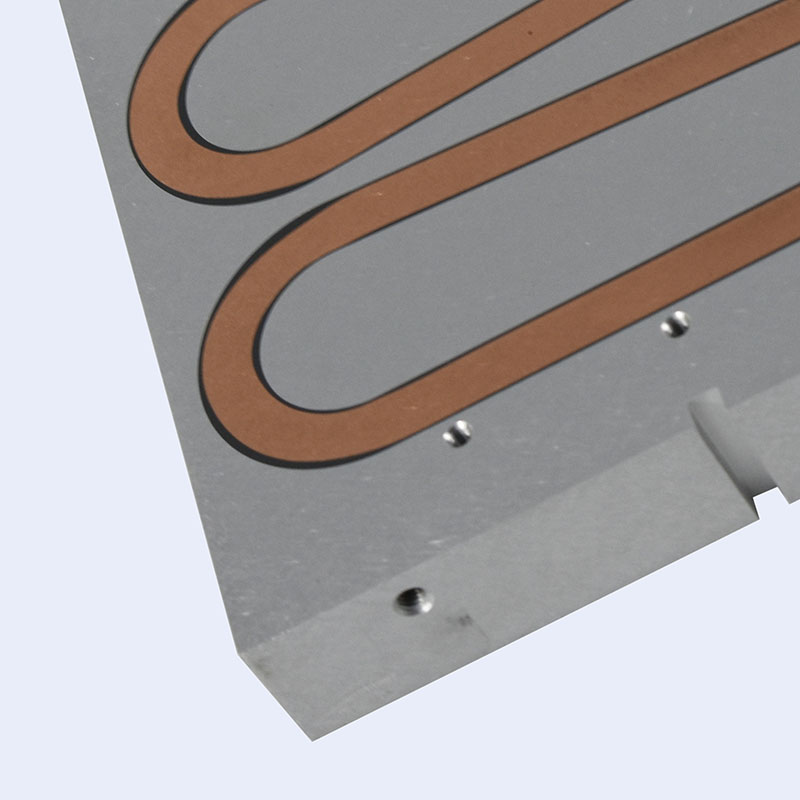

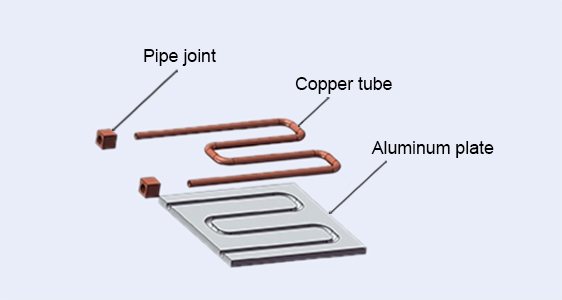

Exposed pipe technique: This technique applies to devices to be installed on one side. Copper heat pipe are pressed to deform into the grooves within an aluminum plate and then a fly-cut is applied to the surface. This allows the quick removal of heat due to the high thermal conductivity of copper heat pipe. Meanwhile, the lightweight of aluminum can reduce the total weight and keep the cost to a reasonable extent.

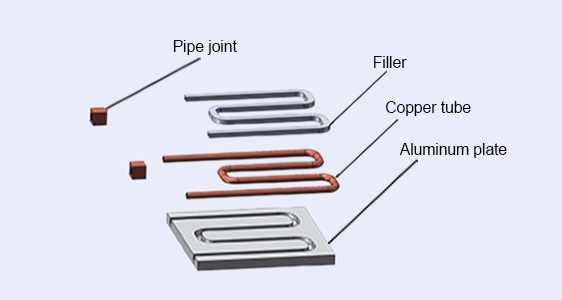

Full-buried pipe technique: The filler is a type of highly conductive epoxy resin which is imported from the US. When the temperature difference between two sides of a device is not critical, the aluminum cold plate can be applied to either just one side or both sides of the device. Since the copper tube thickness is not affected by any secondary machining and the application safety is ensured due to the protection of the filler, this technique is especially suitable for aluminum cold plate applications which use refrigerant as the cooling medium.

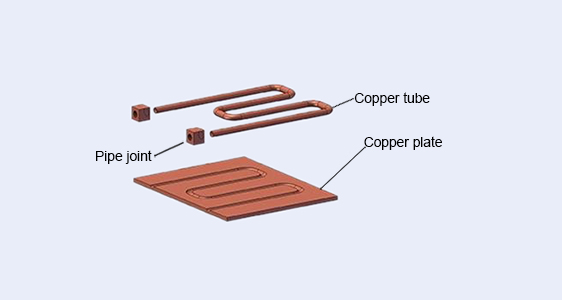

Half pipe techniques: This technique is suitable for the combination of copper cold plate + copper tubes. It can reduce the plate thickness and generate the weight reduction effect.

Sandwiched pipe technique: There are tubes between two plates and this technique is simple with lower cost. The combination could be aluminum cold plate + aluminum tubes/copper pipe/SUS tubes.

Meanwhile, Lori as a cold plate heat sink manufacturer, we also have passed ISO9001:2015, ISO14001:2015, Rohs certification, have enough ability to provide customer with high quality custom cold plate heat sink products and Large-scale production capacity.

1. Cold plate heat sink for high power rectifier (unique integral structure, strong and durable).

2. IGBT, IPM, Square semiconductor cold plate heat sink (good temperature uniformity, long life design)

3. Cold plate heat sink for high power fiber laser, Electric Automobile, Optical communication, Military transmitter, Etc.

4. Friction stir welding use for cold plate heat sink , Frequency converter, laser, power industry, New energy automobile industry, Water cooled electric housing, Motor controller, Etc.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.