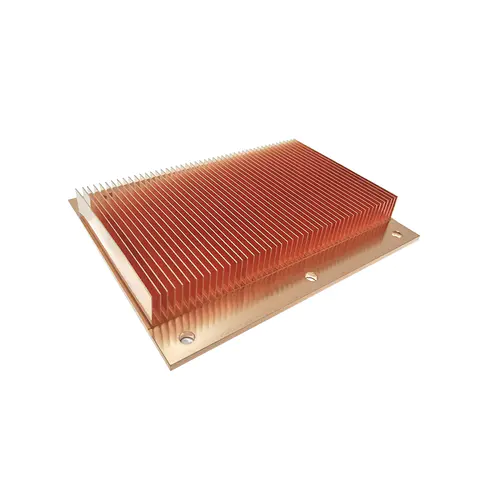

Bonded fins technique is a conventional high power large heat sink manufacturing technique. Bonded fin heat sink may have the bad phenomenon of loose heat sink fins, especially with thick heat sink fins, which will loose or even fall off at a higher rate. LORI Thermal launched several bonding techniques via our own technical innovations and these include highly conductive thermal epoxy bonding, welding, thus, the reliability and stability of cooling are greatly improved and any potential risks are avoided. The features of bonded fin heat sinks include more fins per inch, smaller fin gap, and flexible profile height and width so that they are suitable for different sizes of application space. This kind of heat sink is small in size and light in weight, so it is an ideal choice for cooling high power equipment. Lori bonded fin heat sink wildly applied to IGBT Devices ,Welding Devices, Motor Devices, High Power Semi, Lasers System, Renewable Energy, Factory Automation, Thermoelectric Modules - TECs, Un-interruptible Power Supplies, AC Welding Switches, Power Rectification Equipment, Power Rectification Equipment, Traction Control Motor Drives.·

In the high power applications where significant heat is generated in a small volume, Lori’s bonded fin heat sink designs can meet the packaging needs by increasing the heatsink surface area without increasing volume, reducing thermal resistance by 50% to 66%. Bonding fin heat sink removes the design limiting fin extrusion ratio found in extruded heat sink. Typical extrusion heat sink fin ratios range from 4:1 up to a maximum 16:1; while bonded fin heat sink designs allow ratios up to 44:1 or greater, providing cooling in forced convection for some high power applications. Bonded fins, fabricated from aluminum sheet through extrusion, are bonded to the machined and grooved base with a highly conductive thermal resin.

Bonded fin heat sink features as the following:

1. Higher aspect ratio and high fin density of fins increase cooling surface area so the heat sink with high performance.

2. Lower thermal resistance for the high power device heat dissipation.

3. Aluminum fin, copper base, aluminum base can be assembled into bonded fin assemblies.

4. Fins fabricated from sheet metal or extrusion, custom designs available, the metal plate is made of fins, which can be cut to a specific size.

5. We can customize your wings according to thermal performance requirements and packaging size height restrictions. For more complex designs, we can extrude fins to specific shapes and lengths.

6. Used for high power forced convection cooling applications.

7. Bonding resin with highly thermal conductive for minimal thermal loss.

8. Dissipate more heat than the conventional heat sinks with the same footprint.

9. Reduce heat sink and overall system volume

10. Increase the aluminum cooling surface area by two to three times than traditional heat sink

.

-

Customized Bonded Fin Heat Sink With Heat PipeInquire

-

IGBT Rectifier Heat Sink With Bonded FinInquire

-

Bonded Fin Heat Sinks For IGBT Cooling Solution LoriInquire

-

Bonded Fin Heat Sink With Copper base LoriInquire

-

Custom Aluminum Bonded Fin Heat Sinks For IGBT LoriInquire

-

High Power Led Bonded Stitched Fin Heatsink ForAluminum Bonded Fin Heat SinkInquire

-

Large Bonded Fin Heat Sink For Radar LoriInquire